Types of presses for apples and how to make them yourself?

Presses existed in ancient Egypt, with their help they squeezed the grapes from which wine was made. Such units operate on a cyclical basis: the start of work is the loading of the product, and the end of work is the utilization of dry waste. In private households of the 21st century, press is in demand, and they differ little in principle from those that worked during the time of the pharaohs.

Types of structures and their principle of operation

Press, which allows high-quality squeezing juice, is needed in a private household. Factory-made juicers do not have such advantages as a self-made press. The economic factor is also important, because a good juicer from a branded manufacturer costs a decent amount. The design of presses are divided according to the principle of extraction into the following types:

- mechanical;

- pneumatic;

- hydraulic.

And also, depending on the principle of energy that is used, the presses are represented by the following varieties:

- manual;

- electromechanical.

Important! One should also take into account the fact that vitamins in fruits and fruits are fragile elements. Such compounds are rapidly destroyed by contact with any metal.

It is worth considering an apple press as an example. The main unit of any unit is a special container with drilled holes into which the cut raw materials are put. In the professional language, the original mass is called “pulp”. The juice flows and enters a special vessel. All parts that are in direct contact with the product are made from wood. In order to increase the efficiency of the squeeze, as well as to improve the quality of the product obtained, the raw materials are loaded into the press in special cloth containers of burlap, they are a kind of filter. The process of extrusion itself occurs through the use of special wooden grids, which allows you to simultaneously use the entire working mass.

Many experts note that press better do it yourself. The price of the simplest devices is at least ten thousand rubles. It is important what material is made of the unit, what is its performance.

If the simplest hydraulic drive is used, the price increases by almost 100%. If there is a membrane element in the press, then its cost will increase by 1000%.

How to make your own hands?

To make a handmade apple garden unit yourself, you will need tools such as:

- saws;

- various wooden elements;

- metal corners;

- bolts with nuts;

- hammers;

- keys;

- cutting pliers;

- pliers.

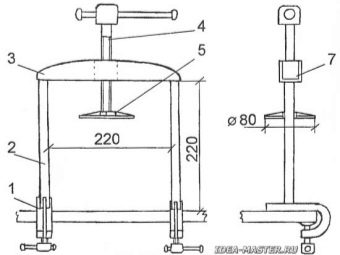

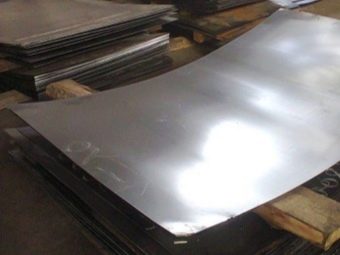

And you will also need a sheet of stainless steel and wooden elements made of oak, birch, beech or alder. Be sure to draw design drawings, and samples can be found on the Internet in the public domain. You need a natural strong fabric with good filtering properties (burlap, cotton). DSP in such structures is not recommended, because this material is often saturated with phenol and formaldehyde.

Manual homemade unit in a private household can be welded from iron, such a unit is easy to quickly assemble yourself. For the plate, which is located in the lower part of the apparatus, it is permissible to use a tabletop. The rotating mechanism is rational to purchase on the trading floor, which sells automotive parts.

And also small hydraulic aggregates are common in households. Hydropress works on the principle of creating pressure due to fluid. In this case, the working cylinder is usually located vertically (sometimes there are horizontal modifications). The hydraulic jack has greater productivity and is capable of creating significant loads - at least one ton, which is enough for fruit. Hydraulic bottle jacks can process large volumes of raw materials in a short time.

Hydraulic

The operation of the device is based on one of the main physical laws of Pascal. The main structural elements are two working chambers of cylindrical configuration, which have different parameters. In a small container, an increased fluid pressure is generated. It is fed through a special overpass into the chamber, which is much larger in size, thus pressure on the piston occurs.

The piston is the main node, which directly exerts a significant force on the mass loaded into the container. Most often, special oils are used as working fluids.

Hydropress can also work with the use of a special elastic barrel. It will increase in volume under the influence of fluid. When expanding, the membrane acts on the raw material, which is folded in a perforated container. Hydropress can be connected to the water supply, the membrane expands in the perforated cylinder itself, which makes it possible to squeeze out all the liquid contents from the pulp.

The pressure must correspond to 1.4-2.1 atmospheres, which corresponds to the technical data of the networks. If there are large volumes of material, you will need an electrically driven press.

The collecting tank is lined with filters from the inside, the raw material is placed into it, and it is covered with a cloth. A circle goes down to the outer part of the cover; it acts on the press as the stock moves. The required pressure can be created using a compressor. To collect the juice, most often involved is enamelware, into which a special tube is sealed, so that the product can flow through it. In the inner area is often put the tank from the washing machine.

You should also create additional perpendicular cross member to give additional rigidity, so that it was possible to place the container in the central part.

It is important to follow the pressure, it should be distributed in all points of the mash with equal effort.

You can fill the cavity with special filtering envelopes that are placed flat. A special locking round device is placed under the container (can be made of wood) so that the pressure could not deform the main container. Without much effort, such a screw press in 4-7 minutes is able to squeeze out up to two liters of fresh juice. A material that perfectly withstands great pressure is burlap, and old nylon tights are often used.

It should be noted that the design of the hydraulic unit, made independently, can be quickly adapted to solve the problem that is required at the moment. Such a device takes up minimal space. A home press is able to create pressure up to twenty tons to make juices, this is quite enough.

Screw

The screw unit has the ability to squeeze out up to three buckets of juice in one hour, which is quite enough for the needs of one family. A very handy fixture is a hand screw press. It does not have high performance, however, the unit can work quite effectively. Often, this type of press is made in a private household. The screw mechanism can press from the top plane with the help of a rotating screw.

If you design a press where lower fixation is present, then more effort will be required, such a device is more complicated, in it the screw upper unit only fixes the cover, no more. The main effort comes from the bottom, a dynamic platform raises the tank up.

If there is no possibility to make a screw pair, then the jack is often used. Between the elements of the tree put the bags of filter material. The product to be processed is placed between the special wooden frames, the juice flows into the container.

The screw piston can be exchanged for a plastic membrane, and also a compressor can be connected so that the most difficult part of the work is performed by pressurized air. Such a unit is called a pneumatic press.Often, car jacks are used to generate the necessary pressure, they can create a force of up to 3.5 tons. It can be mounted both from above and below, which depends on the general device of the unit itself.

The pressure is quite significant, which should be considered when selecting fabric. It should be quite durable. The advantage of this unit is that there is no metal here. The tree can be any, only non-coniferous, so as not to add too much flavor.

The material is not recommended to be treated with chemicals or primers. Plates are made at least 2.5 centimeters thick.

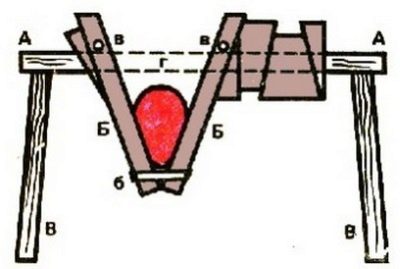

Still practiced fairly original unit, which is called the wedge press. The product is placed in a cone-shaped wooden container. Reducing the angle with moving wedges causes them to move towards the joint. The bag with the product is compressed, the juice, squeezing out, flows into the vessel. This press has the following advantages:

- the design is simple;

- economically viable;

- easy to store and assemble;

- quite high performance;

- the unit is easy to disassemble, clean and dry.

An example is a press made in Turkey. The frame is made of cast iron, and the inner part is covered with silver sputtering. The product is crushed using a lever type mechanism. The work is silent, you can extract from the product up to 75% of useful material in a very short time. It is designed for pomegranate, apples, pears, as well as citrus fruits.

Screw

Such presses operate on the principle of a meat grinder. They have a rotating axis, which is made as a helix, so that the processed mass in the container is ground and gradually moves inside the unit. As a result, it rests against the grate, behind it a new mass creates excessive pressure, juice is squeezed. Such a device has the following advantages:

- lack of vibration and background noise;

- You can get juices from any vegetables and fruits;

- simplicity and reliability of the machine.

Citrus fruits are considered the most time consuming product. The screw aggregate crushes the contents of the fruit, the juice percolates through a special sieve. The cone-shaped configuration makes it possible to carry out all the work qualitatively, simultaneously removing waste.

Useful recommendations

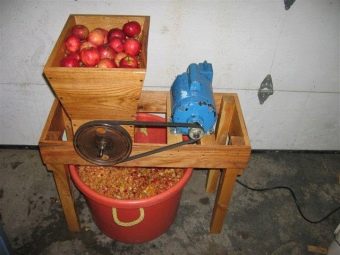

As a grinder, it is best to use a mechanical unit in the form of a cylinder. Its walls should be made according to the grater principle. Using a similar element, the fruit within a few minutes become fine chips. And also there are grinders that can operate on the electrical network, the performance of such devices is large, but in the conditions of a private household they are not very much in demand.

The crusher can be a separate device or unit that is mounted in the press unit. The filter is made of several layers of burlap, as well as perforated plates and a wooden sieve.

Each type of fruit has its own technical indicators; accordingly, different efforts are spent on processing a particular product. When working with a device such as a press, it should be borne in mind that the pressure builds up gradually, with some pauses being made. Such an approach allows the cell capillaries to be maximally opened, which in turn “takes out” all the useful components from the cellular tissue of the product.

A simple home press design makes it possible to squeeze up to 75% of the juice from any product. To determine the choice of hydraulic jack, you must understand exactly what tasks need to be solved with its use. This will prompt the design principle of the manual hydraulic press, as well as the level of pressure that it can create.

How to create a press for apples with your own hands, see below.