Crusher for apples: drawings and manufacturing technology

Apple juice causes positive emotions in most people.But the quality of the product sold in stores does not always meet the necessary requirements. Therefore it is worth getting it with your own hands, using special tools.

Why is this so important?

In principle, you can do without the crusher for apples, using a meat grinder with a special nozzle or even squeezing the juice by hand. But it greatly increases the expense of time and labor. Independent production of crushing devices allows you to simplify your work. In addition, it is much more profitable than buying a finished product. Apple mashed into small pieces allows you to extract more tasty juice.

Wherein:

- the mass of waste is drastically reduced;

- work becomes less tedious;

- It is not difficult to repair crushers designed according to all the rules on their own.

How to make everything?

To make a homemade crusher with your own hands, you will need a typical set of tools that almost all craftsmen have. No special tools needed. The crushing construction happens:

- wooden;

- steel;

- combined type.

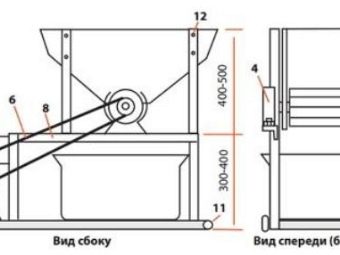

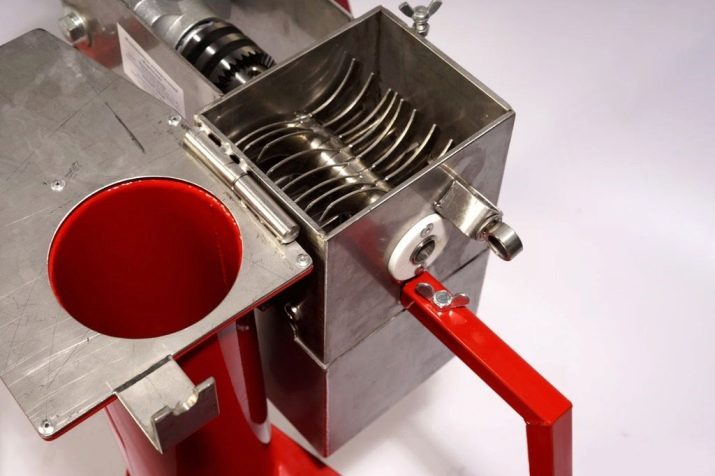

Begin by choosing a sheet of tin. The metal is machined with a lathe, tins for the shaft and bearings are made of tin. In the manufacture of a gear shaft, it is necessary to remove 8 faces, and it is also required to form triangular notches with the aid of angle grinders. The case will be made of an old washing machine that has a vertical load. But designs with horizontal loading will not work.

From the car take the outer part, which consists of stainless steel with a thickness of up to 0.2 cm. When processing a metal billet is required to cut into four segments. Half of them become end elements, and the other two - side parts. Next, you need to connect all these parts using a welding machine. To finish welding the side fragments of steel sheets at the bottom requires a little bend.

When this forms a gap separating the wall from the rotating shaft. It is very important that the shaft is thoroughly secured. If this requirement is not met, the rotation will not be smooth. Recommended mounting on bearing assemblies, such as those used in circular saws. But the vibrating and shaking crusher must be placed very steadily.

Crushing apparatus attached to the support frames. These frames are made with metal corners. Not any tree is suitable for work, but only material from strong breeds. Also, when drawing up drawings, it is required to provide a reservoir for the accumulation of processed apple pulp. This tank is placed under the press.

There are a few subtleties in the design. A frequent problem is the unusually strong bending of the body. Preventing her helps fixing the case to the upper points of the frame at the expense of bolts. It is necessary to provide a place for the installation of wide utensils, otherwise the juice will be sprayed on the sides. A low frame is preferable: with its high position, the flesh will fall down and also cause splashes.

To make it easier to work later, use a tensioned belt. The belt is held by a special bolt. The movement of the main unit will occur along the guide structures. On the frame add rollers and a special handle. Thanks to these elements, the movement of the shredder is greatly simplified.

Assembly of other elements

A high-quality apple crusher should have a device for adjusting the start. Despite the “high-tech” name, there is nothing difficult in this - it means only a switch button. The electric motor is placed on the side of the main structure of the crusher.

With high-quality design and accurate work, home-made crushers often outperform branded products. We need to think over everything so that washing even the farthest corners of the chopper is not difficult.

Work tips

Before you make your own drawings, you should familiarize yourself with the developments of other craftsmen. In order not to look for what motor to put, you can take the motor from the same washing machines or vacuum cleaners. Instead of metal, sometimes wood is used to construct a crusher. This option is much easier to work with. In this case, the container where the apples are to be loaded is made with three horizontal walls, another one is placed at an angle.

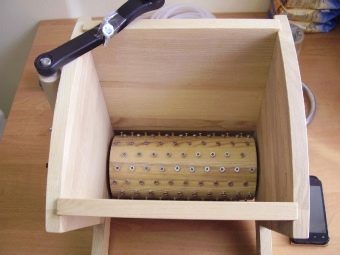

Such a solution has repeatedly justified itself, simplifying the loading of processed products. The shafts are formed of steel or of highly durable wood. The caps of the screws screwed into the shaft turn out to be the teeth, in contact with which even the strongest apple is crushed. For your information: improved performance is demonstrated by structures in which the screws are set in a spiral. It is along this trajectory that the pulp moves.

The size of the bunker is always selected in accordance with the number of apples that are planned to be processed. It is very good when the working chamber rests on a special stand that has legs. From the side where the container will be placed, immediately make a hole. The size of the passage should also be selected in accordance with the performance of the crusher. The original way to drive the shaft in motion - using a drill:

- the axis is immediately brought out;

- on this axis fit the tip of the drill;

- Such a solution helps to ensure rapid rotation and recycle a large amount of apples in a short time.

It is useful to think about replaceable nozzles. They help achieve a variety of chopping fruit. Some knives make extruded round holes. Others also make an extruded recess, but in the form of a slot. Still others squeeze the hole again, this time having burrs.

Recommended parts

For mounting parts crushers among themselves use:

- M8x20 screws, having a hexagon inside;

- screws to hold knives with convex warheads M3x8;

- bolts M12x25;

- Allen screws M10x16 and M10x25;

- bearings series 6307;

- cup washers IS6731-32;

- round nuts with splines version M32x1.5.

additional information

All parts that will be in contact with food are required to be made of stainless steel of suitable grades. When selecting the diameter of the pulleys, it is necessary to focus on a standardized series of parts with a transmission coefficient of 2.

Crushers for apples allow you to confidently process also the flesh of pears. Aluminum pots can be used as a reservoir for fruit mass. You only need to drill holes in it on the perimeter at the same level.

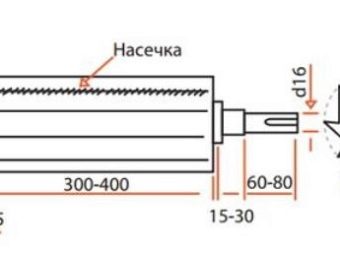

Another production version of the working chamber involves the use of a cylinder made of stainless steel. The length of such a cylinder should be 0.4 m, and the diameter - 0.2 m. The winding of screws is made both on the left and on the right. It looks like a spring for a car. This technique allows you to radically reduce the noise at work.

How to make a grinder for apples with your own hands, see the next video.