Cheese Tet de Moine: characteristics and recipe

Cheese Tet de Moine can be counted among the symbols of the Swiss Confederation. It has a rather interesting name - Tete de Moine, which means “monk’s head”. Gourmets prefer this type of cheese for its savory taste with a sweet touch.

Special features

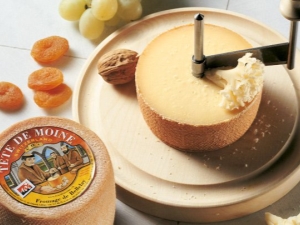

Tet de Moine is in the top of the most expensive cheeses produced in Switzerland. It is made from milk cows. The weight of one cheese head reaches 1 kg, and its ripening period ranges from three months to six months. The product is not cut in the traditional way, but by means of fatty. The result is that the top layer of chips, which looks like a miniature rosette, is scraped off the cheese. Many still compare this shavings with chanterelles. There is a reason for this: the adaptation zhirol is exactly translated from French - “chanterelle”. Such cheese pieces are suitable for decorating any dish.

Cheese has a very delicate structure. Raw materials are boiled in copper boilers, and aged on spruce shelves in purpose-built basements. For a long time, cheese was in circulation as a currency, so it was excellent in its taste characteristics. The recipe for making Tete de Moine has been known for 800 years, but it is kept in the strictest confidence. Place of production - Belle Abbey in the city of Bern.

Important! Cheese is perfectly combined with semi-sweet or dry white wine. The product is served on a wooden plate with grease. One movement - and the most beautiful cheese bud is already on the dish.

Cooking

In order to make cheese, which in its visual and taste characteristics resembles the famous Tête de Moine, You will need the following ingredients:

- cow's milk (fresh) - 10 l;

- water, pre-boiled - 5 l;

- dry thermophilic base - 2 g;

- sea salt (without iodine) - 1100 g;

- white mold Geotrichum candidum - 30 mg;

- calcium salt of hydrochloric acid 33% - 1 tbsp. l .;

- calcium salt of hydrochloric acid 10% - 2 g per 10 ml of milk;

- calf rennet (in liquid form) - 0.5 tsp;

- Vinegar 9% - 1 tsp;

- dry aromatic base Danisco Choozit - 1 g;

- aromatic red brevibakteriya - 30 mg.

From the prepared ingredients you get one cheese head, weighing about 1 kg. In addition to certain products, for the production of cheese Tet de Mouans requires special devices such as:

- 12 l enamel pan;

- saucepan 15 l;

- food thermometer;

- wooden spoon with holes (can be replaced with a plastic one);

- cheese press;

- knife with a long blade;

- sets of measuring spoons and cups for cheese making;

- cylindrical form press with high walls;

- gauze fabric or muslin.

Before starting the preparation of cheese, all tools must be sterilized. If for some reason this cannot be done, the process can be simplified: thoroughly rinse the instruments and scald them with boiling water. In the original, fresh milk is used to make cheese.

When choosing an unpasteurized product, it is necessary to slightly adjust the cooking nuances, namely:

- to heat the cheese is necessary not up to +36, but up to +38 degrees;

- no need to add a solution of calcium chloride;

- the amount of rennet and starter need to be reduced by 1/5 part.

The recipe below uses pasteurized milk. Cheese is prepared for two days, and then set aside from three months to six months for its ripening. A few hours of the first day are given to the formation of soda (grain) and 19 hours - the time for pressing the product. The next 16 hours is the time allotted for salting the cheese. So, the cooking process involves several important steps.

- Milk put in a pan with water and heat over very low heat. Stirring regularly, bring it to +36 degrees. While the milk is warming, it is necessary to add the calcium salt of hydrochloric acid and mix well, so that the substance is distributed proportionally throughout the liquid. Then add a thermophilic base and Danisco Choozit. You just need to sprinkle the last one and wait until it is soaked with milk. Then mix. To start the starter, the pan must be closed with a lid and infused for half an hour. Heat can be stored in a saucepan using towel winding.

- After this time, the milk must be thoroughly mixed and add rennet, mix the milk mass from the bottom up. Again close the container and wait 40–45 minutes until the milk coagulates. A more accurate time, which is necessary for milk to coagulate, can be determined by the formula K = F * M, where M is 2.5, and F is the time of condensation. The resulting value in minutes and will be the time for which you need to leave milk for the origin in it of the necessary physical and chemical processes.

- Then you need to try to separate the clot. If its consistency is not sufficiently compacted, it is better to leave the mass to infuse for another quarter of an hour. Then cut it into small square pieces. First cut vertically, then perpendicular. The clot heats up to the mark of + 45– + 54 degrees. This should be done slowly for half an hour. A higher heating temperature causes a smaller grain size in the cheese and, accordingly, increases its density.

- While the clot is heating up, it should be continuously stirred and crushed too large lumps. After bringing to the desired temperature, remove the pan from the stove, let the clot stand for a while and settle to the bottom. The resulting whey is drained, but not completely, but so that the grain is covered with a layer of 5 cm. Then the cheese grain must be collected in one room and put it in the prepared form.

The formation of the future cheese in a single layer should be done under the whey layer so that there is no void between the grains. If you ignore this rule, mechanical gaps and the wrong pattern on the surface will appear in the cheese head.

- In order for the self-pressing process to take place, the form with the prepared mass must be left in serum for a quarter of an hour. Then put under a press of 4.5 kg for a third hour. Remove the cheese head from the mold, turn it over with the other side and wrap it in a new cloth. Extrude another half hour with a weight of 7 kg. Turn the cheese over again the other side, leave for 6 hours under a 10 kg press. After that, put the cheese pressed by the other side for half a day and weighs 17 kg. While the cheese is being pressed, it is necessary to make a saline solution and put it in the fridge all night.

- In the morning remove the product from the mold, remove the fabric. Lower the head into the prepared brine for 16 hours, not forgetting to turn the cheese every 3 hours for uniform salting from all sides. During salting the cheese must always be in the fridge. After the required time has elapsed, the cheese is removed from the brine, soaked with paper napkins and sent for maturation into a room with a humidity level of about 80% and a temperature regime not higher than +14 degrees.

- During the first few days a cheese crust is formed, therefore, to ensure uniform drying, the product should be turned over at least three times a day. After the crust has dried, the humidity indicator in the room should be increased to 90%.

- The first month the head of cheese on the shelf for storage needs to be turned every day, subsequently - 3 times in 7 days. If there is an opportunity, you need to leave the cheese to ripen on the shelves of pine trees, it is from them he will get his unique flavor.

- The dried crust needs to be wiped daily with brine from Brevibacterium linens. This procedure should be repeated for as many days until the crust becomes rather dense and becomes salmon-pink. Brevibacteria are designed to make this process more dynamic.

After 2.5 months, the cheese will get a tangerine-colored crust, and its taste will be soft and tender. In six months, the cheese crust will become a rich brown shade, and the taste will be spicy.

Production

Cheese is produced in only 10 Swiss factories located near the Bernese Alps. Any food colors, flavors and flavor enhancers are not added to the product. This is a completely natural cheese, made on the basis of milk of Alpine cows. The price for such a delicacy is high - 3.5 thousand rubles for 850 g.

In the next video you will find a recipe for veal tenderloin with Tet de Moine cheese.