Normalized milk: what is it and how is it made?

In order for dairy products to be consumed without risk to health, they undergo various processing. However, in some cases, additional work on the composition and taste is necessary to match the products with individual preferences and variety of the range. In this case, the process of normalization of milk.

What does it mean?

On the shelves of stores today presents a huge selection of dairy products, in particular, cow's milk. This variety is not limited to the names of trademarks, as well as domestic or foreign origin. Quite often, the name “normalized milk” can be found on product labels, which, as a rule, makes the potential buyer think about the naturalness of the presented product.

However, the emerging concerns are completely groundless, because it is completely natural milk, whose composition was brought to a certain level of milk fat content. This indicator by technological processing of raw materials may increase or, conversely, decrease.

The manufacture and sale of such a product is not accidental, the need for normalized milk is due to the fact that the fat content of the product can vary from 0.1% to 8%. And the ability to offer the consumer products in such a wide range has led to the demand for technology normalization, since the level of fat in the original product is directly dependent on the breed of cattle.

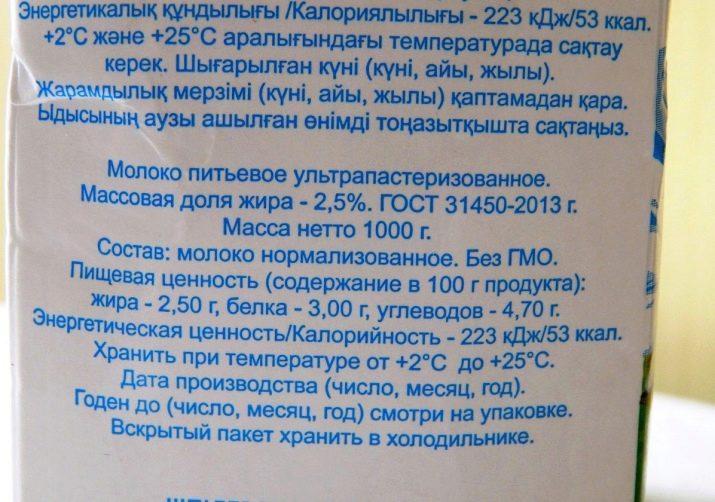

Normalized milk is produced according to GOST. Based on the prescribed norms, bringing the mass fraction of fat, protein and milk powder is carried out exclusively from components of animal origin, which indicates the presence of restrictions on the production of dairy products in the composition of the components of synthetic or vegetable origin. Unfortunately, sometimes the goods, the production of which occurred in violation of the established rules and with the inclusion of prohibited and low-quality ingredients, still arrive at the store shelves.

Given the information on the product described above, we can say that normalized milk, the production of which occurred in accordance with GOST, is a natural and safe product. And the only difference from the pair is the level of milk fat.

The undeniable advantage of normalized milk is the fact that the consumer will always know how much fat he uses, which is relevant for people who have health problems. In addition, this issue is of paramount importance for the category of buyers who are watching their weight or are suffering from obesity. According to the recommendations of many nutritionists, the optimal fat content in milk for humans is from 2 to 4%. This is especially true of the developing children's body.

Despite the heat treatment, which is necessarily carried out during the production of normalized dairy products, it is still worth buying a product that will have a minimum shelf life, since it will be most beneficial to health.

The composition of the product

Milk is a useful product because it contains a large number of important micro and macro elements. Considering the composition of the product, it is worth highlighting the main nutrients.

- Milk contains a lot of calcium, and since the element is associated with organic molecules, it is absorbed many times faster by the human body.

- The product retains phosphorus and potassium.

- Milk is emitted with a good content of vitamins of groups A, B, D, E. However, in a fully skimmed product, vitamins A and E are present in a minimal amount.

- Antibacterial components help strengthen the immune system.In addition, they have a beneficial effect on the gastrointestinal tract, as a result of which it is possible to reduce the acidity of gastric juice, get rid of heartburn, etc.

- Phenylalanine and tryptophan have a beneficial effect on the nervous system, improving sleep.

- Regular consumption of the product helps to eliminate toxins from the body.

Milk has a slight diuretic effect, due to which blood pressure is reduced.

What is different from the restored?

Whole and reconstituted milk are products that are produced in completely different ways. In the first case, the product passes only heat treatment before entering the shelves. No processes that would affect its composition and the level of milk fat content are carried out. It is this milk that is further used for the preparation of normalized products, in which, thanks to special technologies, the percentage of fat content is reduced to the corresponding values. In addition, it is worth noting that there can be no powder ingredients or other additives in it.

As regards reconstituted milk, in this case the situation is somewhat different. The fundamental difference lies in the process of manufacturing the product. Recovery technology is based on milk production using dry milk product. As a rule, such processes are practiced in production in regions where there is an acute shortage of natural raw materials due to a number of factors, including seasonality, the presence of cattle, etc.

Another reason why some production facilities are concentrated on the production of reconstituted dairy products is the pricing policy that has emerged for this product line. In the consumer market, reconstituted milk falls into the category of budget goods.

How do they do it?

Normalized milk undergoes a certain process of pasteurization. For these purposes, companies engaged in the manufacture of dairy products use modern technologies for processing incoming raw materials. In addition to asking milk the required percentage of fat, the processes it takes in production, can significantly extend the shelf life.

All work with products is carried out in special production tanks, which are equipped with mixing equipment. Today, several tasks of processing whole cow's milk are used to complete the task. It should be noted the main ones.

First of all, it is necessary to mention such a process as sterilization. The essence of the technology comes down to boiling the dairy products entering the plant.

- To increase the fat content in milk, the method of inclusion in the initial composition of a similar product, but having a higher indicator of fat content, can be applied.

- The technology of separation involves an increase in fat content in an artificial way.

- The method of pasteurization, which is carried out according to strictly established standards and requirements.

Skimmed milk or cream is used as a normalizer in the course of work. Not so long ago, similar processes in the villages were carried out by infusing fresh milk in the cold until the layer that is the richest in fat is formed on it, and it was separated from the main mass. Now the cream from the product at dairy plants is decanted or artificially separated. These processes make it possible to divide the milk into two different in fat content of the product, but in a shorter time. Also, the works that are carried out at the plants additionally disinfect the product, which cannot be said about the methods used earlier.

Among the features of the technological processes of making normalized milk is worth considering that the work on mixing products of different fat content with skimmed milk or cream are carried out with the obligatory homogenization.This process is to bring the working fluid to a uniform state by grinding.

All of the above technologies, which are used in dairy enterprises, suggest a preliminary accurate calculation of the required amount of fatty or fat-free product, by applying the material balance equations. Similar calculations can be performed for all products and components of normalized milk, without exception.

Work with the cream separator occurs as follows. The original product enters the separator. It is the process of dividing the liquid into two components. After that, the two products are connected in a stream in a certain ratio. Based on what percentage of the fat content of the product must be obtained, an extra portion of cream or nonfat product is discharged.

All fat content control processes are carried out automatically. For work, the normalization control system in the flow and a similar system in which there is a separator are used. By controlling the processes with the help of specialized equipment and programs, it is possible in the end to get stable and clear indicators of the mass fraction of fat and other parameters in normalized dairy products.

The main tasks that are pursued during the application of technologies for the normalization of milk, in addition to bringing to the desired value of its fat content, also include the removal of possible excess inclusions from the product and, importantly, the destruction of microorganisms dangerous for human health and bacteria. In addition, today not everyone can use whole milk, which has the smell of a cow, the normalization of the product eliminates the original flavor completely.

The fact that such a normalized milk and for the need to normalize the product can be found in the video below.