What and how to make milk powder?

Today milk is one of the most vital products for the proper growth and development of the human body.According to the natural features, a newborn baby and a baby mammal receive the main set of nutrients and nutrients from their mother's milk. Its composition has all the necessary vitamins and trace elements in order for the body to grow and become stronger. An adult, already possessing a strong body, still needs a systematic use of milk.

Benefits and contraindications

Thanks to production technologies, we have the opportunity to use milk daily both fresh and modified (ryazhenka, cream, curds, butter, yogurt). Milk, depending on the processing method, can be whole, skim, steamed, baked, condensed and even dry. In the case of our usual dairy products, as a rule, most people have no questions. While dry milk on the territory of our country is not a widely available product, and therefore raises many questions and conjectures.

Despite the bias towards dry milk, in reality it is not inferior in terms of the content of useful and nutrients in the composition of the raw cow analog.

Powdered milk has a number of useful properties.

- With regular use of milk concentrate, there is a decrease in the symptoms of anemia, the level of hemoglobin in the blood is normalized.

- Cholesterol levels are normalizing.

- The chlorine content in the product contributes to the removal of edema and general cleansing of the body.

- Thanks to magnesium and phosphorus, provides comprehensive support for the healthy development of the body.

- It is recommended as a prophylactic agent for diabetes mellitus and gastroenterological diseases.

- It is a rich source of vitamin B12 and natural protein. It can be used as a meat substitute for people who have excluded it from their diet.

- Easily absorbed, while not creating discomfort in the digestive tract.

- There is no need for pre-heat treatment when consumed, as the drink does not contain harmful microorganisms.

- It contains a balanced complex of vitamins, as well as proteins, fats and carbohydrates.

There are no significant contraindications for this product, except for individual intolerance. In this case, an allergic reaction may occur.

It is not recommended to abuse dry milk to people actively leading the fight with extra pounds. The essential energy value of the product will contribute to weight gain. However, this is an obvious advantage for people involved in fitness, the purpose of which is to gain a general mass.

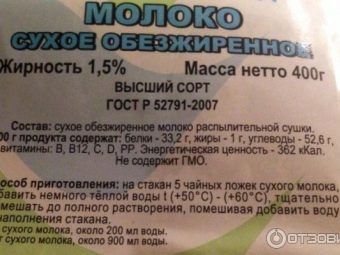

Composition

The composition of milk concentrate is almost the same as that of whole cow's milk and makes it look like. The difference lies in several elements that are destroyed in the process of manufacturing this product. Main cast:

- proteins, which are the main building material for the human body;

- fats, which are energy microparticles, which are the main participants in metabolism;

- lactose, popularly referred to as milk sugar, is essentially a complex carbohydrate that contributes to the proper flow of the energy process;

- a set of vitamins and trace elements necessary for the proper development and growth of the human body.

The energy value per hundred milliliters of the product is forty-nine kilocalories. When the fat content of the product is two and a half percent, the amount of proteins is three grams, and carbohydrates - almost four. In the absence of violations in the manufacture of milk concentrate, the composition retains most of the useful, nutrients and mineral components.

One hundred grams of milk powder contains vitamins:

- A - 0.13 mg;

- B1 - 0.01 mg;

- B2 - 0.02 mg;

- C - 0.4 mg.

In addition, the milk concentrate contains a small amount of calcium, sodium, potassium, phosphorus and magnesium - they provide comprehensive support to all the processes occurring inside the body.

During the production process, some of the vitamins found in cow's milk break down. In connection with this fact, the compositions of fresh and dry products are different. However, the minerals contained in the composition of fresh milk are not afraid of heat treatment at high temperatures, and therefore their content remains unchanged in dry concentrate.

This product is fully capable of replacing a fresh counterpart. Its use contributes to filling the body with the necessary forces, fills the deficit of calcium and other vitamins, does not cause difficulties in digestibility and does not harm the digestive tract. Dry milk concentrate is recommended for people suffering from diabetes.

At the same time, the presence in the composition of a significant amount of vitamin B12 makes it possible to fill the need for essential nutrients for a person who voluntarily refused meat. Of the obvious advantages, it can be noted that the milk concentrate does not need boiling, since the product undergoes thorough pasteurisation during industrial drying, which means that the presence of harmful microorganisms is excluded. Of the disadvantages can only be noted the possible occurrence of an allergic reaction. As a rule, this happens to people with acute lactose intolerance.

How to produce?

In Russia, the production of milk concentrate is carried out in five stages. The raw material used is fresh cow milk, which undergoes some modifications.

- Standardization - at this stage, technologists achieve a certain level of fat contained in the product. For this there is a rule that is considered a kind of "ideal" to which they aspire. For example, a low-fat product is subjected to procedures that increase it. Conversely, a high fat product is customized to a lower one. To change the indicator, add a product with a low fat content or, conversely, rich cream. This stage is obligatory, as it is necessary to produce a product that would comply with regulatory documents.

- Heat treatment - The second stage of the production process for the production of milk powder. Heating fresh cow's milk is necessary for the destruction of all harmful microorganisms and bacteria in it. Production pasteurization does not take much time, after which the pasteurized milk is cooled.

- The third stage in the manufacture of milk concentrate is cooking, often referred to as thickening. During thickening, pasteurized cow's milk is boiled, at the same time separating into whole and skimmed milk. Each species has its own cooking time. When sugar is added to the product at this stage, everyone receives a well-known and favorite delicacy - condensed milk.

- At the fourth stage of the production process is carried out milk homogenization. This process is a mechanical treatment of dairy products, which is characterized by the grinding of fatty elements that are in the composition of milk, through external influence (pressure, ultrasound or high-frequency electrical processing). In other words, at this stage, technologists achieve a uniform milk consistency.

- The final stage of the production of milk powder concentrate is drying The resulting nutrient mass is dried in a special device until the product acquires a certain level of moisture.

Proper breeding at home

To use milk concentrate or use it as a substitute for whole cow milk, it is necessary to give it its original appearance, for this purpose liquid is added. For dilution of milk powder, a standard ratio is applied - one to three. That is, one part of dry milk concentrate is taken into three parts of any liquid. Proportions can be modified depending on the desired result.

In order that the first acquaintance with this product does not cause you frustration, it is advisable to adhere to the following recommendations.

- Do not use cold liquid when diluting milk powder. The fact is that the low temperature of water or coffee contributes to the crystallization of the milk concentrate with the formation of visible lumps. The use of such a drink is not a pleasure.

- Using an excessively hot fluid is also undesirable. Otherwise, in contact with boiling water, the milk concentrate will simply collapse.

- It is recommended to pre-pour the powder into the container and only after that fill it with liquid, otherwise lumps will form.

- The use of a blender or mixer is undesirable, since the whipping of diluted milk powder results in the formation of unnecessary foam.

- After you dilute the dry milk concentrate, leave the drink to infuse for a short time.

You will learn more about what and how dry milk is made from the following video.